National high-tech enterprise

| Has been dedicated to powder forming technology for 18 years

NEW Rotary powder forming machine

MULTI-STATION FORMING EFFICIENCY IS BEYOND IMAGINATION

Brand-new pressure holding technology can improve 10% productivity

Position: Home > powderpress

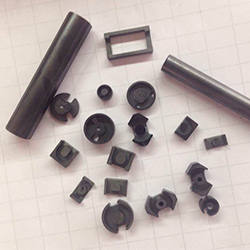

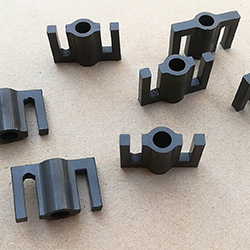

APPLICATION FIELD

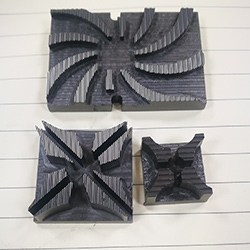

This equipment is formed (different shapes) by forced pressure on metal power or non-metal powder as raw materials. Frequent materials include graphite powder, ceramic powder, magnesium zinc, nickel zinc, manganese zinc, iron powder zinc, iron silicon, FeSiAl and aluminum dioxide powder, pills powder forming.

Good equipment for good products

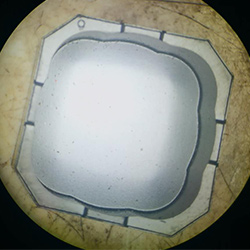

3.0 PRESSURE HOLDING SYSTEM HAS MORE UNIFORM DENSITY

The blank yield rate approximates to perfection and can improve precision much

With a half automatic operating system, one worker can operate multiple machines.

This machine is easy to operate and understand and one operator can know how to operate after 2-min learning

Technical consulting

One-time acquisition for whole-life service

1-TO-1 TECHNICAL ADVISER PROVIDES YOU WITH SERVICES

Since you express an intention, you will have one 1-to-1 technical adviser to provide technical service. If you have any demand, you can contact us at any time

Team

Service team

Mr. Wu

Senior technical adviser

Mr. Wang

Senior technical adviser

Miss He

General production control director

HO'S

Machine model parameters

| # | Model | Station | Parent larger outer diameter | Forming diameter | Imposed pressure | Dimension |

| 1 | 200-P | 9 | 47 | 10 | 2T | 696x627x1727 |

| 2 | 250-P | 9 | 47 | 12 | 7T | NO |

| 3 | 300-P | 12 | 57 | 12 | 10T | 830X26X1907 |

| 4 | 400-P | 8 | 90 | 25 | 20T | 1152X1024X2212 |

| 5 | 530-P | 8 | 100 | 30 | 35T | 1215X1214X2532 |

| # | 1 | 2 | 3 | 4 |

| Model. | 200-P | 250-P | 300-P | 400-P |

| Station. | 9 | 9 | 9 | 9 |

| Outer diameter. | 47 | 47 | 57 | 90 |

| Forming diameter. | 10 | 12 | 12 | 20 |

| Imposed pressure. | 2T | 7T | 10T | 20T |

* Tip: Now we provide optional A, B and C series and more than 10 models. Different machines can be customized according to different demands, materials and sizes to satisfy the forming requirements of different enterprises

DEFAULT SERVICE

- FREE DIE

- A free die will be provided for each purchased equipment without any additional die manufacturing cost. After the equipment is delivered to the factory, it can instantly put into production.

- FREE INSTALLATION AND COMMISSIONING

- Technicians shall arrive at the factory together with equipment and provide free whole equipment installation and commissioning service.

- FREE TRANSPORTATION

- We freely deliver goods to customers within the specified area in China except remote areas.

- ONE-YEAR REPAIR GUARANTEE PERIOD

- If equipment fails due to any non-human fault within 1 year since the equipment is received by signature, we will freely repair it.

VALUE-ADDED SERVICE

- NEW DIE

- We will give 5% discount of our die price for any customer who has purchased our forming machine.

- MACHINE REPAIR

- We provide value-added services such as forming machine repair and accessory replacement. For any demand, contact us.

- DIE REPAIR

- We provide value-added services such as forming machine repair and accessory replacement. For any demand, contact us.

1.CONFIRM PLAN

A CUSTOMER SHALL SELECT PROPER MODELS OR CUSTOMIZED MODELS ON DEMAND.

2.CHECK PRICE

AFTER THE FINAL MODEL IS DETERMINED, THE BUYER AND SELLER SHALL CHECK THE PRICE.

3.CONTRACT AND DEPOSIT

The buyer and seller sign a contract and the buyer pays the deposit.

4.PLACE AN ORDER FOR PRODUCTION

The factory schedules orders in its production plan.

5.SHIPMENT

AFTER SHIPMENT, COMMISSIONING AND ACCEPTANCE, THE BUYER SHALL PAY THE BALANCE PAYMENT